|

Shearing

Industry Consultants |

|

||||

| Consultancy | Exercises | Shearing Pattern | Comb Preparation | Manual | Shed Design | Woolhandlers |

|

Shearing

Industry Consultants |

|

||||

| Consultancy | Exercises | Shearing Pattern | Comb Preparation | Manual | Shed Design | Woolhandlers |

| Shearing Comb Preparation

The industry has many different names for this practice - Spinning, Dressing, Experting. They all mean "Preparing Combs" Learn the facts on Sharpening Shearing Gear - Click here |

| Each shearer has different down pressure, angle of approach, and touch. To get the best performance a shearer needs to have confidence in the comb that is being used, on the sheep being shorn. It is important to be able to run the comb on the skin and keep it there, without getting hooked up or riding off the skin. As there are many different types of sheep, a shearer needs to have combs that are able to be used in these various types of sheep. |

| Some combs may need to be thin to be able to get under the dense or sticky wool, others can be thicker so in better shearing sheep the handpiece can be pushed faster with confidence.

If there are only thick combs available they may need more of a point, or less, depending on the shearer using them. There are many combs on the market to choose from, different widths, bends, concaves, convexes, bevels, top and bottom teeth, numbers of teeth, teeth lengths, scallops, side scallops, gullets, etc. Each is made for certain people, sheep, or situation. Some shearers can get a certain type and brand of comb that suits them on certain sheep. |

| Manufacturers are always looking to improve their product, and are therefore continually changing and refining to suit certain markets.

All parts of a comb have a specific purpose. Click for Parts of a Comb The most important part to many shearers is the bevel The bevel is the part of the tooth which starts at the sheep side of the comb and finishes at the tip. It is an arc, which is part of a circle and is measured by it's radius, long bevel long radius, short bevel short radius, etc. The scallop is where metal has been removed from the grinding side of the tooth from the tip back. The scallop puts the tip closer to the skin and makes the comb enter easier when it is new and thicker. Scallops vary in length from short to long. The side scallop is where metal has been removed on the side of the scallop, which may help with entry in some sheep |

|

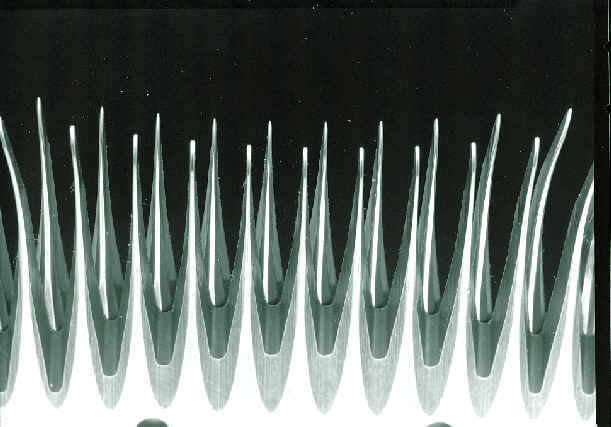

Shearing Combs will always enter the wool easier if the comb teeth are

Fine, rather than Thick

|

|

| Too Thick

The thick teeth may not enter or part the wool as well, and can push the wool down in front of the teeth which will allow the comb to ride up off the skin Extra down pressure is needed to keep the comb from rising Too Fine The Fine teeth enter and part the wool easier, but may also slice the skin Lighter pressure is needed to keep the comb from running into skin If a comb does not perform when needed it can be changed. The teeth can be made finer and shaped to suit each person. The process is very easy |

|

|

The Teeth on the closest comb are thicker, and will not enter

the wool as easy as the comb furthest away

The furthest comb has finer teeth and will always enter the wool easier Try pushing a comb with thick teeth into the pages of a closed telephone book, from the side Next try pushing a comb with finer teeth into the pages and see the difference.

|

|

|

If

you have a comb that doesn't enter as well as you would like, or it picks up skin more than other combs, it can be altered to suit you or the

sheep

If it isn't changed it will probably sit in the bottom of your comb holder and not get used at all It may just be the teeth need thinning, or reshaping Usually the first tooth to check is the bottom one Is it too thick on the tip or on the bevel? If so then you need to thin it slightly There are different ways to do this. You may use wet and dry carborundum paper, a slip stone, a bright boy or other abrasive products. |

|

They can all achieve similar results if used properly. - Have a Go, or You'll Never Know |

|

Learn the facts on Sharpening Shearing Gear - Click here |